I have good reasons for cutting off this first double-binding rag rug before proceeding with the rest of the warp. This pause and reset ensures happy weaving to the end. Cutting off gives me a fresh start for the next rug.

Reasons for cutting off rag rug before end of warp

- Uneven warp tension. I can improve the warp by tying back on.

- Large rag rag. I can get a tighter warp tension by removing the rug’s bulk from the cloth beam.

- New design. It helps me to see the completed rug before starting the next one, since this is a brand-new design.

Steps for cutting off rag rug before end of warp (countermarch loom)

- Replace shaft holders. Insert shaft pins.

- Insert locking pin(s) in the countermarch.

- Tie lease sticks to back beam.

- Release tension back and front.

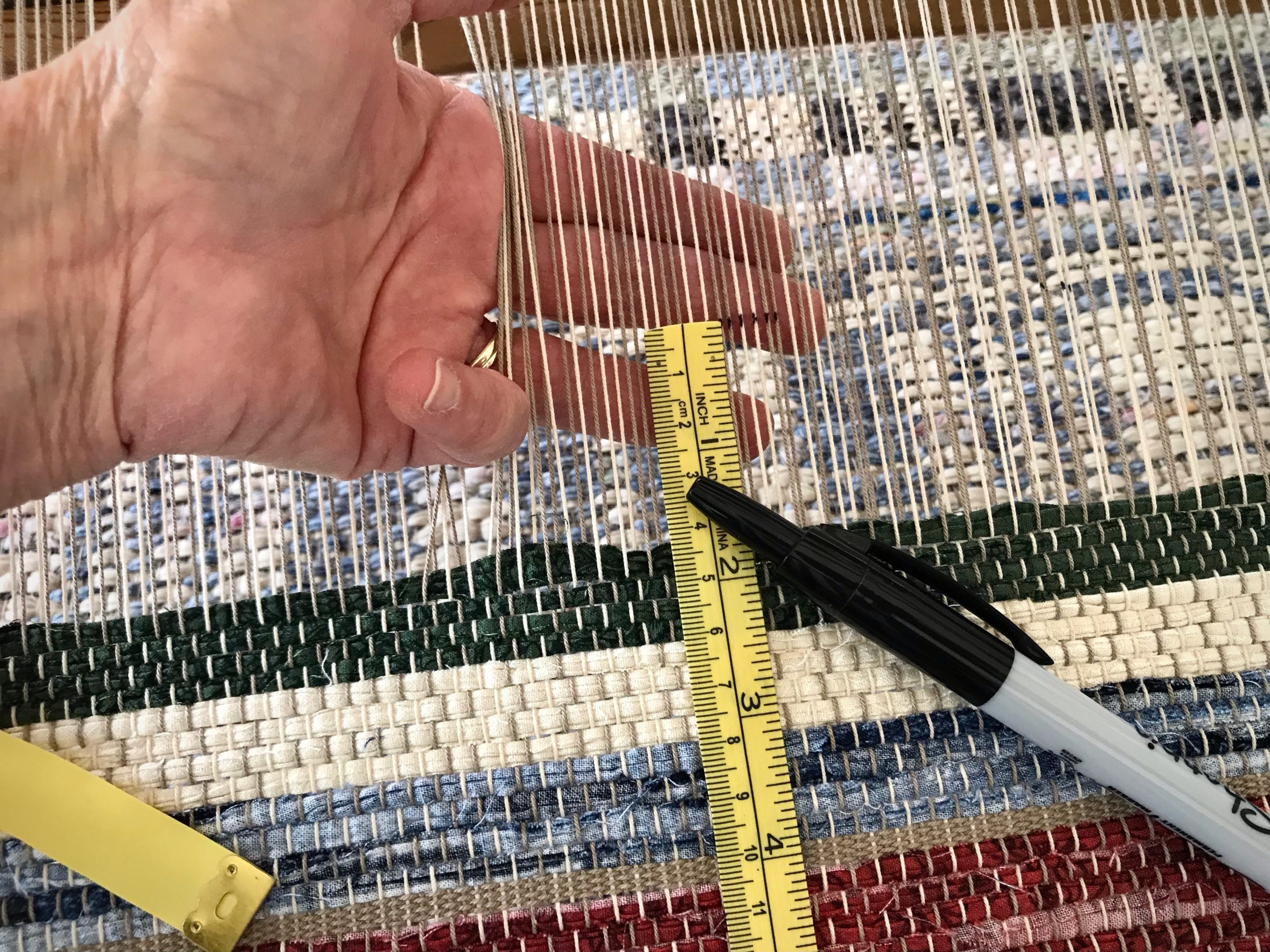

- Mark a cutting line across the warp with a black marker. Allow at least 10 centimeters (4 inches) beyond the rug’s warp-thread header for tying knots later that will secure the weft.

- With tying back on in mind, cut one group of ends and skip the next group of ends. Continue across the warp, alternating cut and uncut groups of ends. Tie groups of cut ends in slipknots as you go.

- Make a second pass, cutting the remaining groups of ends, and tying them in slipknots.

- Unroll the rug from the cloth beam. Take a photograph.

- Lay the rug out on the floor. Ooh and aah.

May you get a fresh start whenever you need it.

Happy Weaving,

Karen

Great article s well as pics

I teach weaving at the elementary school grades 3-6

The older kids love weaving rugs, it’s great mediation, kids feel calmer they say

IMPROVED gross and mortar coordination. They love color too

We also make napkins, dish towels mug rugs, placemats and book marks to sell

We also teach reading labs to evaluate fiber content and what country they come from

Not to mention child labor laws and climate change

Question: we iron the strips that are 1 1/2 inch wide and fold edges in. Do you ?

Thanks susan

Hi Susan, I’m impressed with the value you are bringing into the children’s lives. Thank you for doing that.

I cut my fabric strips 3/4” wide. No folding or pressing. I cut the ends of the strips in a taper and overlap the tapered ends in the shed, so no stitching of strips, either. This is the most common size of strips and method that I have seen in the Swedish books that I have. I enjoy weaving in a Swedish style.

Thank you,

Karen

Good morning Karen,

My wheelhouse!!!

Thank you.

I concur with your reasons for cutting off a finished project and re-tying the warp.

I’ve been using filler cut from t-shirts and sweat shirts. I love the automatic roll that occurs when the t-shirt rag strips are pulled. It does make a thick rug.

A concern of mine is how to clean a larger rug. We have sandy soil, a wood burning fire place, and free range chickens.

My washer does have a handwash cycle that works for the smaller rugs.

Last week I met a woman who quilts. She described how she washes them. She fills a large Rubbermaid container with soapy water. Puts in the quilt. Goes Lucy and Ethel on it. Changes the water until it runs clear. Then line dry.

When the weather warms up, I’m going to try that on my larger rag rugs.

Hi Nannette, I wash large rugs outside on our back deck. I lay them out flat, spray them down with the hose and then scrub them with a soft brush and small amount of soap. (Some rugs don’t need soap at all, just a good spray down.) Then, spray them down again to rinse. They can dry flat, or hang over the railing, or hang over the back of chairs on the deck. Flip them over from time to time to help them dry.

A wet rug (or quilt) is too heavy for me to wash and lift from a tub.

All the best,

Karen

Peter Collingwood would put on endless meters of warp for his rugs. On the Collingwood Harrisville rug loom…there is a warp extender which cranks to the top of the castle. As one weaves, the extender would be slowly lowered…all the while keeping perfect tension. Peter removed the woven rug and tied on, time after time. He declared the tension for each rug was best by this method.

Hi Charlotte, That is good to know. Peter Collingwood certainly knew about weaving rugs. It confirms what I’ve experienced in getting the best tension if I cut off each rug and tie back on. Tying on isn’t hard, and I’ve concluded that it doesn’t use any more warp than putting spacers between rugs.

Thanks so much for your valuable input,

Karen

Ooh and ahh indeed! Thank you for sharing. This looks like it was a fun project. You have inspired me to give it a try. Did you follow any specific pattern or is this your own design?

Hi Kathryn, It is indeed a fun project. I’m glad you like it. It is my own design, based off of a drawdown in Landes Book of Drawdowns, no.1a, and the double-binding threading from “Alskade Trasmattor,” by Hallgren and Hallén.

Thank you,

Karen