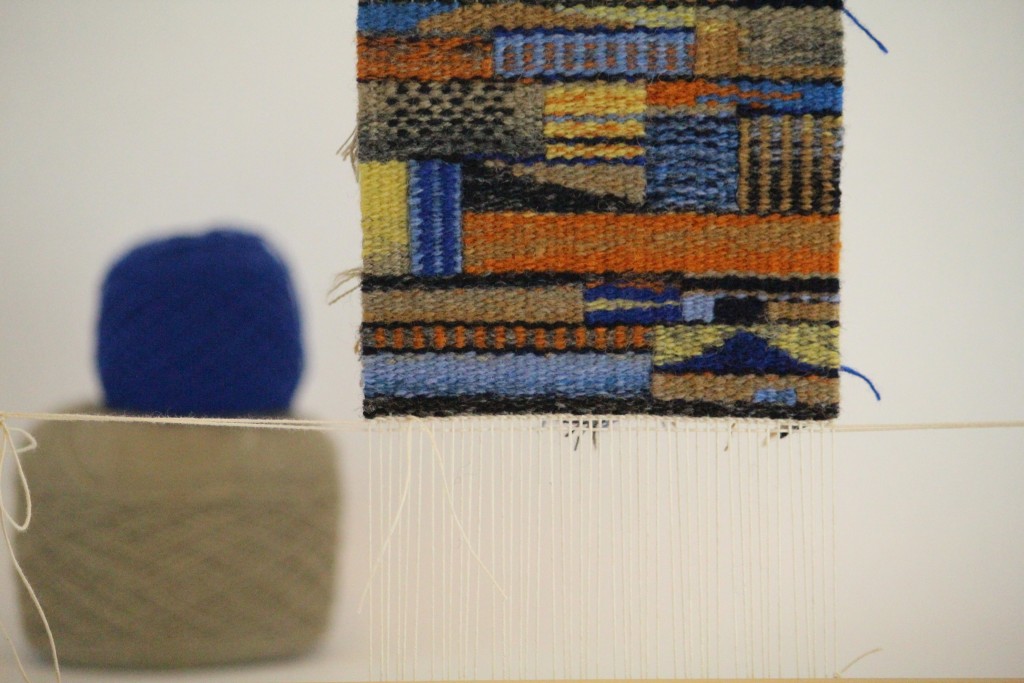

The wool double-width blankets came out even better than I had hoped. It still seems magical to simply weave, and end up with cloth two times the woven width. What did I enjoy most about this project? First of all, the colors. It is so much fun to mess with colors. Secondly, the fringe. I love how the fringe turned out. Those chubby twists are my favorite part of the finished blankets. Knotted, or not. The first blanket has knotted fringe. Watch the Wool Blanket Final Finishing video below to see what happens with the fringe on the second blanket.

In this final episode in the Wool Blanket Finishing series, I show you how I brush the blanket and finish the fringe.

In case you missed any of the previous videos in this series:

1. Colorful Cozy Blanket and a Video

2. Quiet Friday: Wool Blanket Finishing

May your work come back to you as rewards.

Love,

Karen