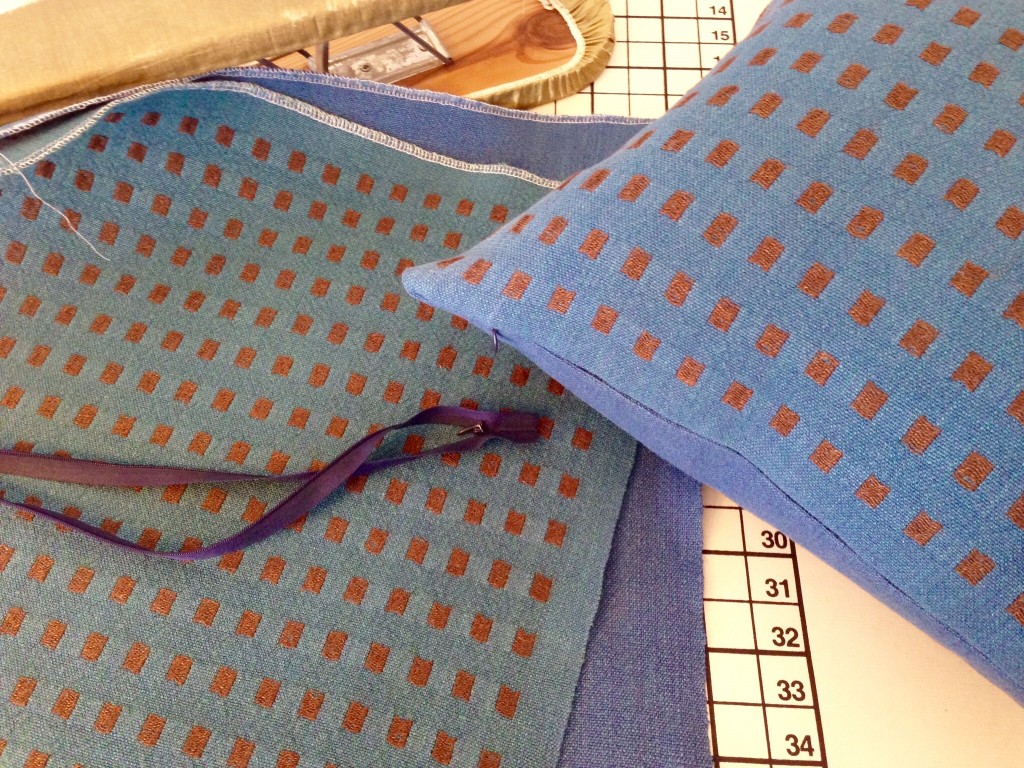

Do you see the lengthwise raised ridges in this linen fabric? Don’t be fooled. The plain weave panel of this fabric is as flat as can be. Optical illusion. I have two slightly different colors of linen in the warp, unbleached and golden bleached. Instead of strictly alternating the colors, I threaded the warp ends “as they came,” to bring depth and interest to the plain weave fabric.

We can be fooled by what we see. Lines and colors work together to create a false impression. Coming close enough to touch and examine is the best way to help the eyes see what is real. How many things do we misunderstand because we fail to come near enough to truly examine the evidence? We assume that a distant view is reliable.

Humility sets the stage for learning. It removes distance between us and what we need to learn. Instead of trusting only what we see, we step nearer to touch and examine the real thing. The humble are teachable. They know there are things they don’t know, and they are on a quest to learn. With weaving, and with matters of greater importance, like faith and truth, we must come close enough to touch and to learn.

May you hold valued fabric in your hands.

With much to learn,

Karen