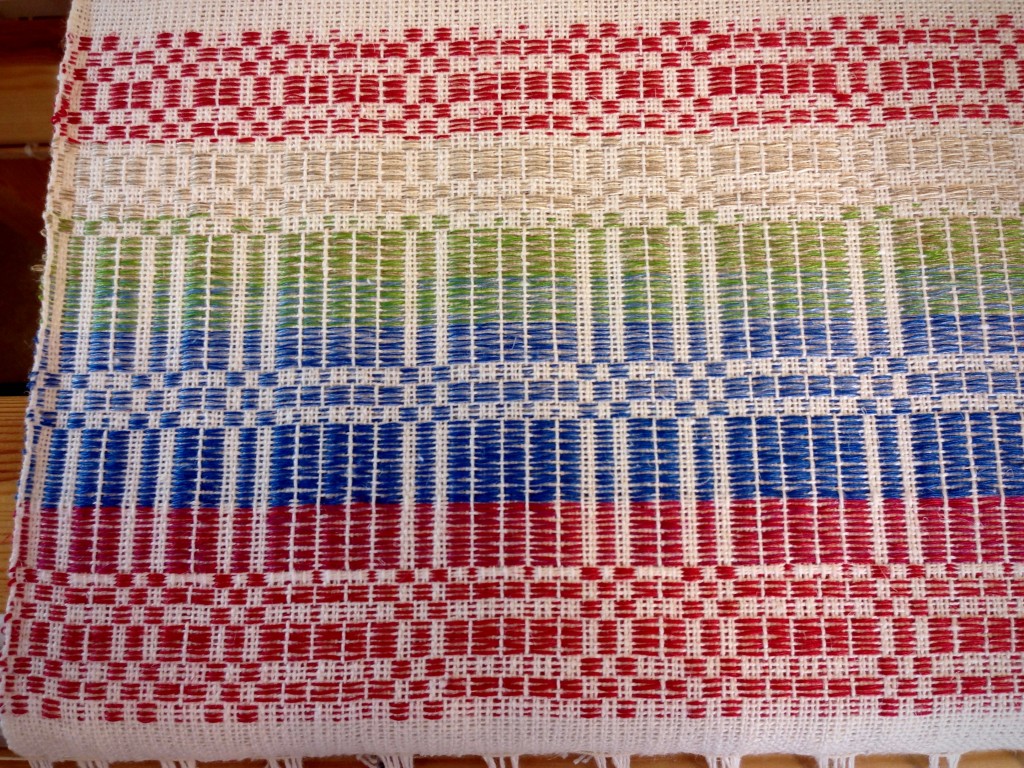

If it weren’t for Christmas, this would be one of those times I would wish for a longer warp. Why is this halvdräll so enjoyable to weave? Simplicity and complexity, cottolin and linen, two shuttles, and interesting treadling. This peppermint red and white is striking and cheerful, and makes the weaving studio feel like Christmas!

I may have it off the loom by Christmas. I am going to try, because I would love to have this festive cloth on the table Christmas Day as my gift to our family. Our children and their spouses, and the four grandchildren, and one on the way!… All will be here with us to celebrate together. That’s a beautiful gift. Family.

The most extravagant Christmas gift is the Son given to us. The majestic choral and instrumental lines in Handel’s Messiah have familiarized an ancient prophecy. Can you hear the singing as you read these lyrics?

For unto us a child is born,

unto us

a son is given,

and the government shall be upon his shoulder;

and his name shall be called

Wonderful,

Counselor,

Almighty God,

the Everlasting Father,

the Prince of Peace.

May you be surrounded with beautiful gifts.

Weaving Christmas,

Karen