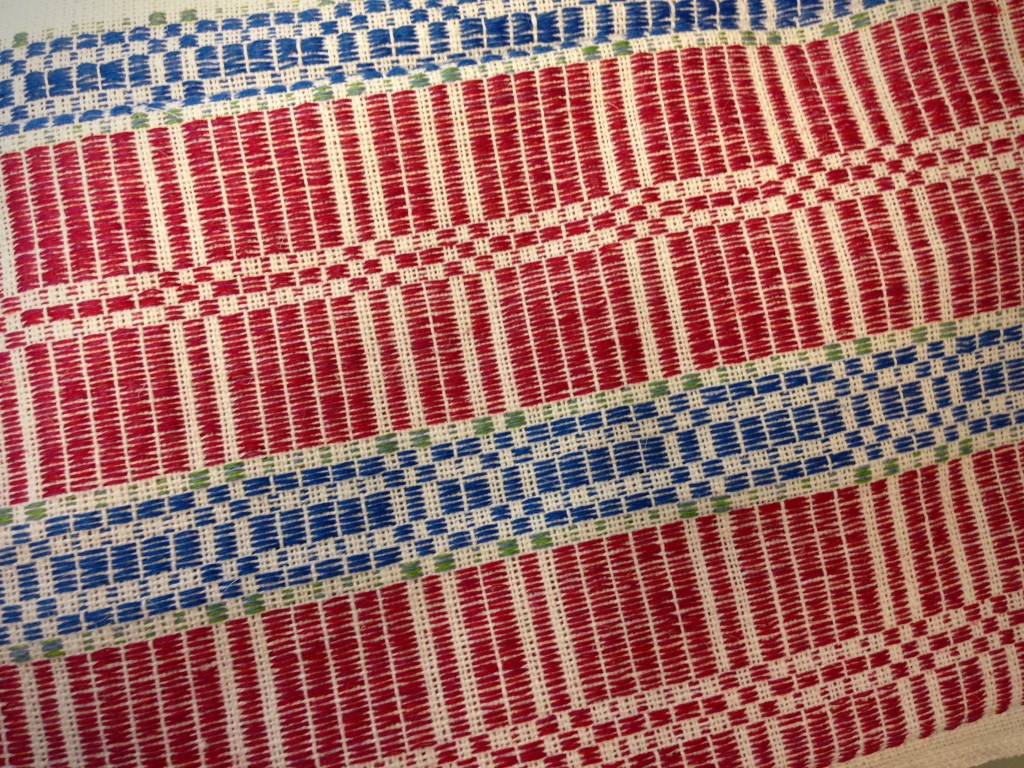

It is possible to ruin hours and hours of handweaving efforts with a careless or ignorant misstep after the cloth is cut from the loom. Wet finishing intimidates me for that reason. Besides my own limited experience, I rely on instructions from advanced weavers, and any other research I can find. In the end, I take the plunge and hope for the best. If the worst happens, I take notes and chalk it up as a learning experience.

Wisdom is gained by those who pursue it. What is wisdom? Wisdom is truth being applied to real life situations. The wise become wiser still by listening with the intent to hear the meaning. Listening and learning. And then wisdom leads you to take action, often irreversible, because you believe the outcome will be right and good. How delightful when the wet-finished fabric exceeds your highest hopes!

May you become wiser than you are today.

In pursuit,

Karen