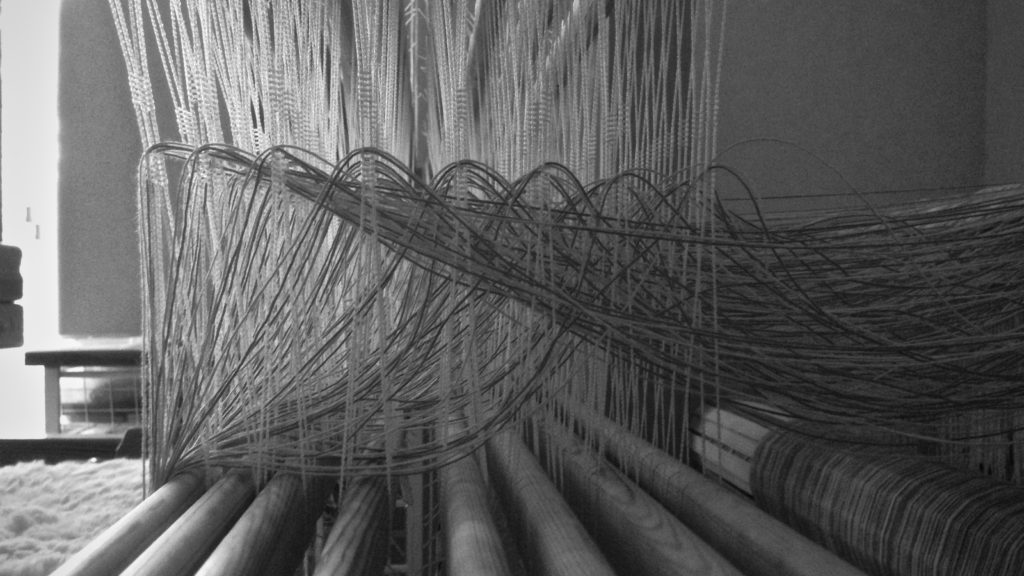

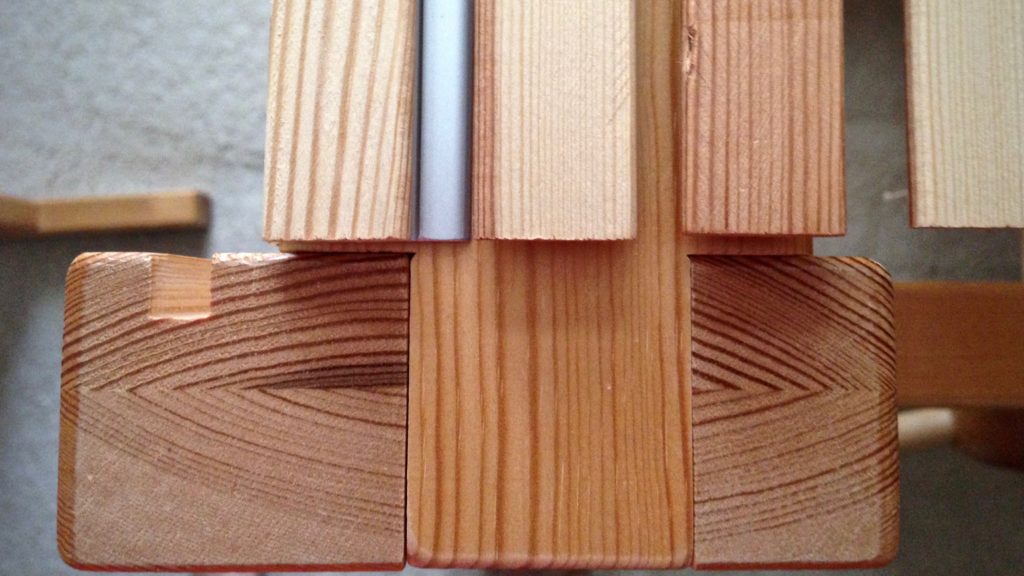

Important things are happening below the warp on my eight-shaft countermarch loom. Eight upper lamms, eight lower lamms, and eight treadles beneath the lamms are at work. Shaft cords connect shafts to lamms. Treadle cords connect lamms to treadles. When the loom is all tied up, stepping on a treadle raises some shafts and lowers others, making it possible to send the weft across in a shuttle. And weaving happens.

Everything below the surface matters. When you start weaving, it won’t take long to see if all the connections work. When everything behind the reed and underneath the warp is set up properly, you can expect a pleasant weaving experience.

Joy is evidence of what is happening below the surface. You can see joy on the face of someone who looks to the Lord and trusts in Him. Joy is more than a smile. It’s a radiance that starts on the inside. Trusting in the Lord produces positive connections below the surface. That deep trust is formed through life’s most difficult moments– joy that is cultivated there endures. Like weaving on a countermarch loom, joy depends on true connections.

May you have reasons to smile.

Joyful Weaving,

Karen