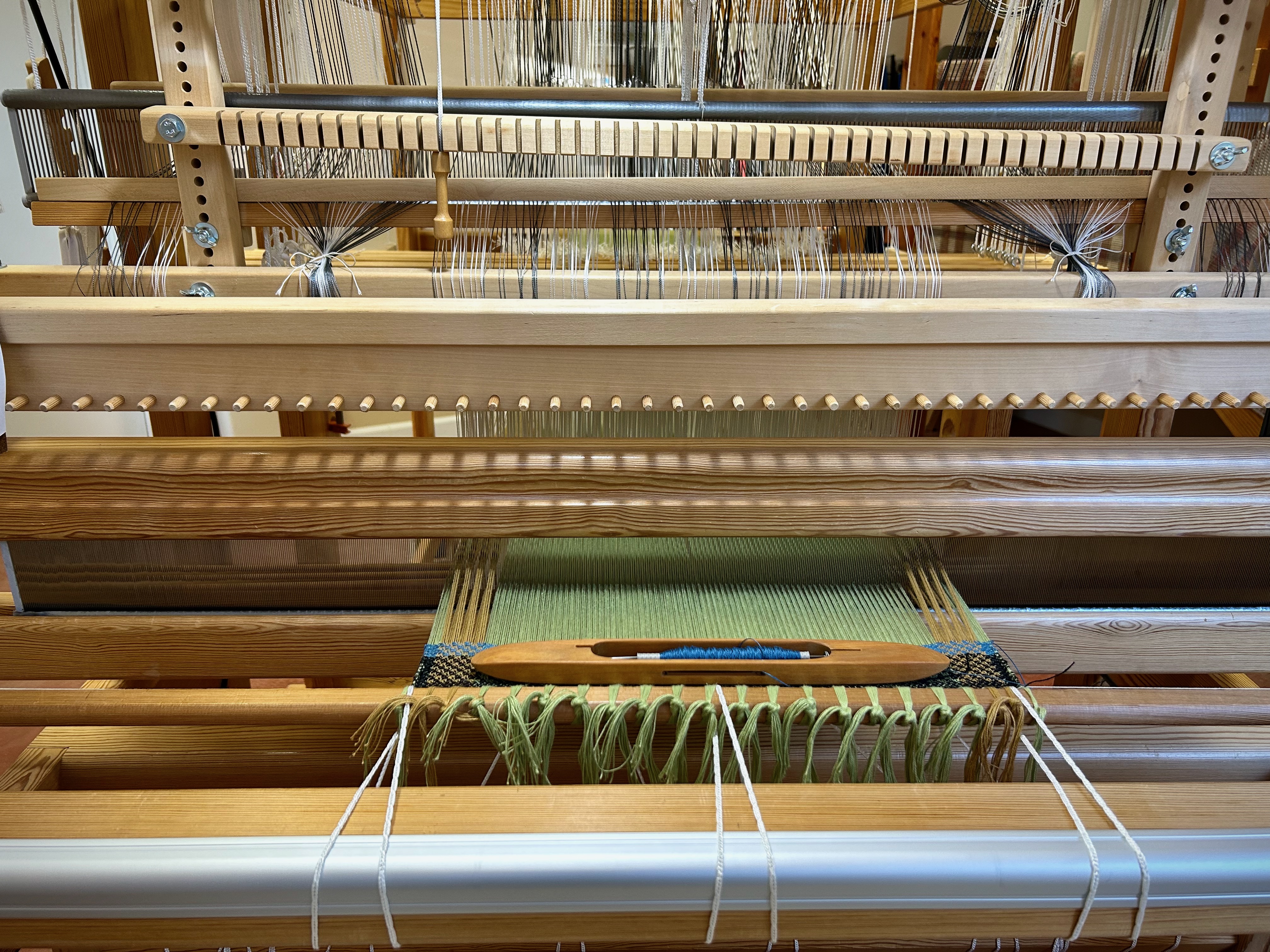

Merry Christmas! Julia is getting dressed with 7/2 Brage wool for a lovely goose-eye twill. Warp chains like this are big and squishy, just begging to be hugged.

This project is going nearly full width on this 70 cm Glimåkra Julia countermarch loom. My warping slats are exactly 67 cm. (I should have measured the warping slats before I started.) At 65.7 cm weaving width I’m asking for trouble. You can see the problem, right? Those ends can slip right off the edge of the warping slats on the warp beam. I got ‘er beamed, though, with the help of a friend. Hallelujah! The warp ends all ended up in the right place at the right time.

If we mortals celebrate such earthly victories, imagine the hallelujah’s that all heaven expressed when the Son of God came down to us in the right place at precisely the right time as baby Jesus. That manger in a stable in Bethlehem was not a centimeter nor a millisecond off. This was God’s plan from the beginning to come in person to bring back to himself all who would receive his offer of lasting grace. Hallelujah! The angel chorus rings out, “Glory to God in highest heaven, and peace on earth to those with whom God is pleased.”

May you see the Christmas story in a meaningful way.

Have a truly blessed Christmas,

Karen