I always put on more warp than I need for a project. That end of the warp is where I play, experiment, and try out crazy ideas, not to mention try to use up the thread from as many quills as possible. Or, for rag rugs, I try to use up as much of the weft fabric strips as I can. I have containers for those odd pieces (remnants). That is where I look when I want to make something.

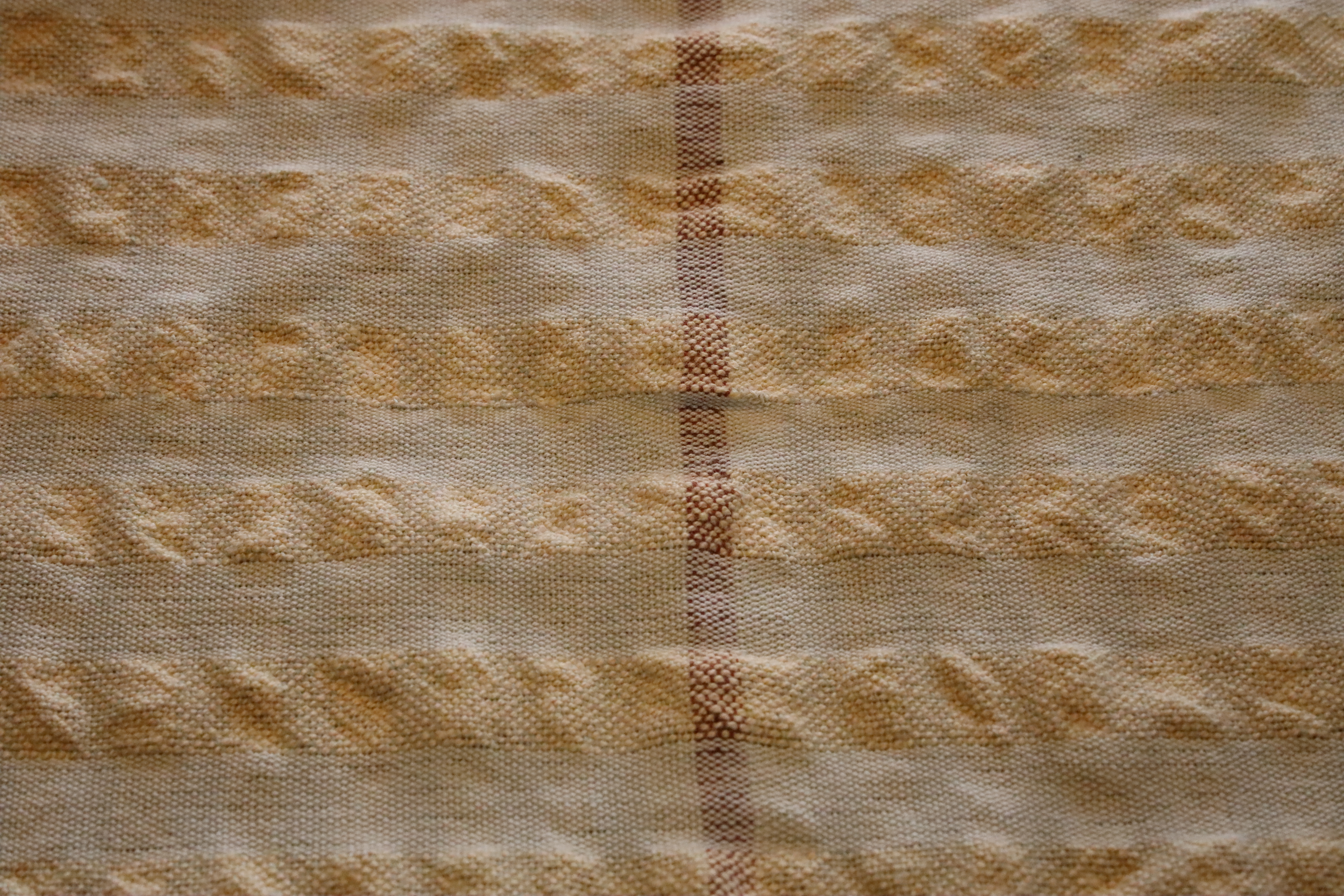

The seat cushion I made for myself last year works great. Now I want to make a seat cushion for me to use in the other car. Time to get out that container of “scraps.”

Less than thirty minutes for this project, from selecting the fabric to inserting the pads. That’s exactly why I always put on extra warp! You never know when you will need an odd piece of handwoven something…

Happy Weaving, Karen