Even though there are dozens of needles in and around my weaving and sewing spaces, nine stand out from the rest. These go-to needles have earned special favor. As essential tools, these needles have specific holders and permanent homes.

- Sharp needles: hand-hemming, hand-sewing, stitching on labels, and stitching a tapestry to a linen mat for mounting (curved needle)

HOLDER: Pincushion I made in 1980

HOME: Sewing supply closet, “Needles and Pins” drawer

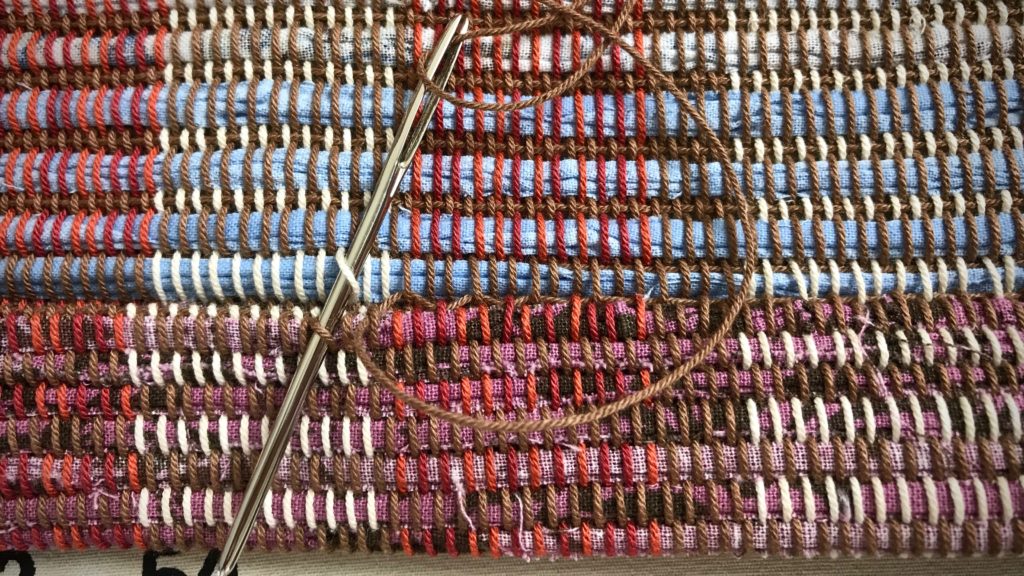

- Blunt tapestry needles, small and medium: hemstitching, stitching a thread mark to the right side of the fabric, sewing in tapestry weft tails, finishing work—needle-weaving for corrections and repairs

HOLDER: Remnant of cotton handwoven plain weave fabric

HOME: Loom-side cart, top drawer

- Blunt tapestry needles, large: hemstitching, hand-hemming rugs, weaving small tapestries

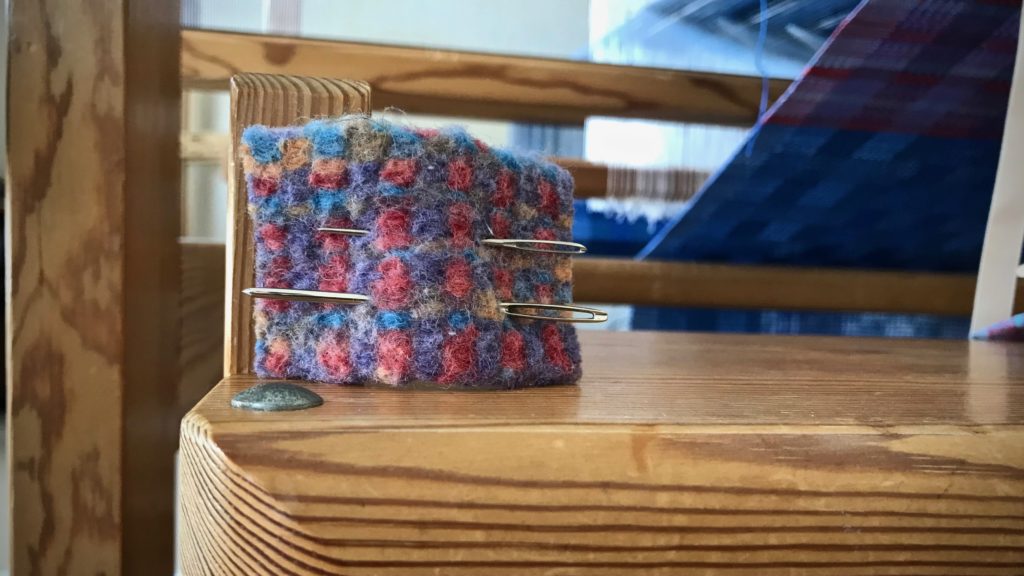

HOLDER: Felted inkle-woven tape

HOME: cutting/work table, Grandma’s old sewing tin

- Sacking needles: pulling rag rug warp ends out of scrap weft, threading warp ends back into a wool rug (I did this…once)

HOLDER: straw-woven pouch from a trip to The Philippines

HOME: weaving supply closet, top drawer on the left

May you find the needle you need when you need a needle.

All the best,

Karen