Eventually, I would like to have a metric reed (or two) in every possible size. Until then, I will be happy with what I have, while I gradually add to my supply, as needed, one reed at a time.

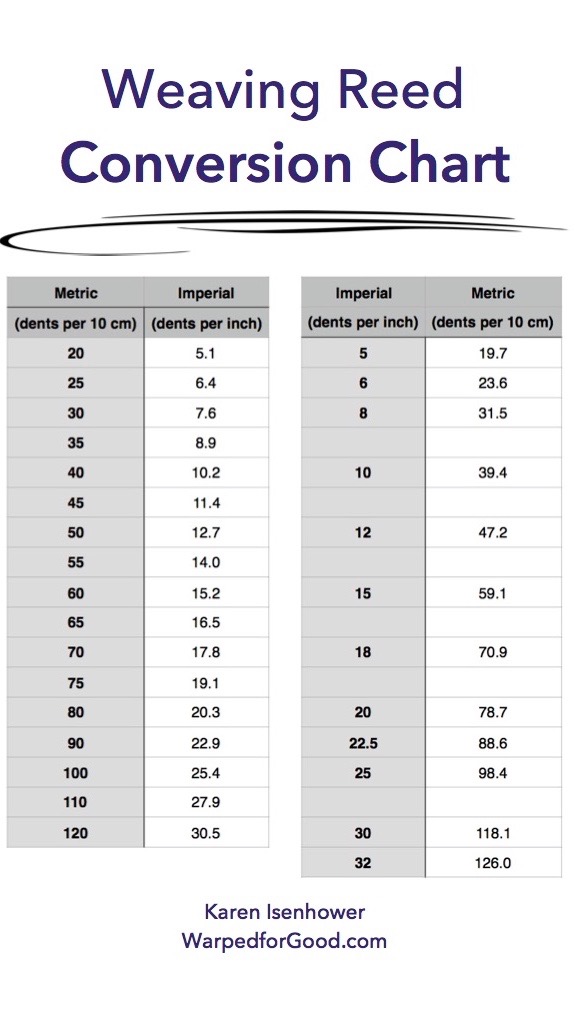

I prefer metric reeds (dents per 10 centimeters) over imperial reeds (dents per inch). For one thing, the math is easier for project planning. And because there are smaller increments between sizes, there are more sett choices with metric reeds. It could be my imagination, but it often seems that the metric reed yields a Goldilocks “just right” sett.

My selection of reeds vary in length, from 70 cm (27″) to 120 cm (47″), to fit the weaving widths of my looms. But Glimåkra countermarch looms have beaters that are open on the sides, so I can use any length reed in any loom.

My all-around favorite reeds are those made by Glimåkra because they are lightweight and easy to handle, …and they come in metric sizes. (Of course, you need to choose reeds that work with your loom.)

I put together a reed conversion chart so that we can see our options at a glance. You never know when a new project will “require” a new metric reed!

May your next project have a Goldilocks “just right” sett.

Happy weaving,

Karen