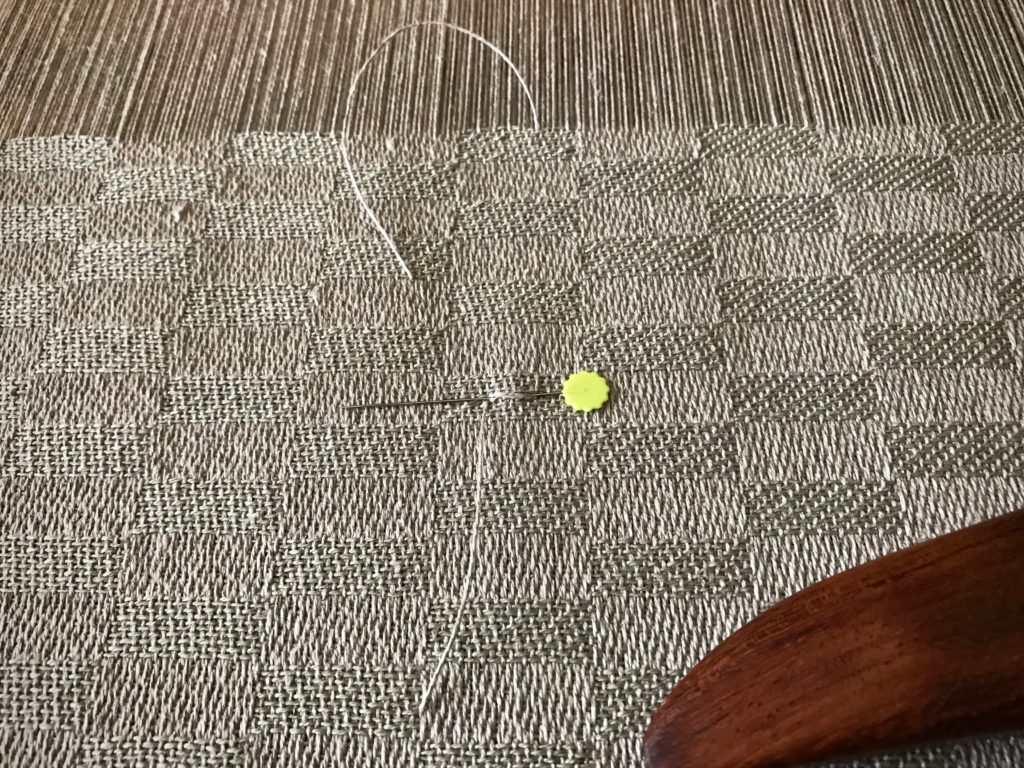

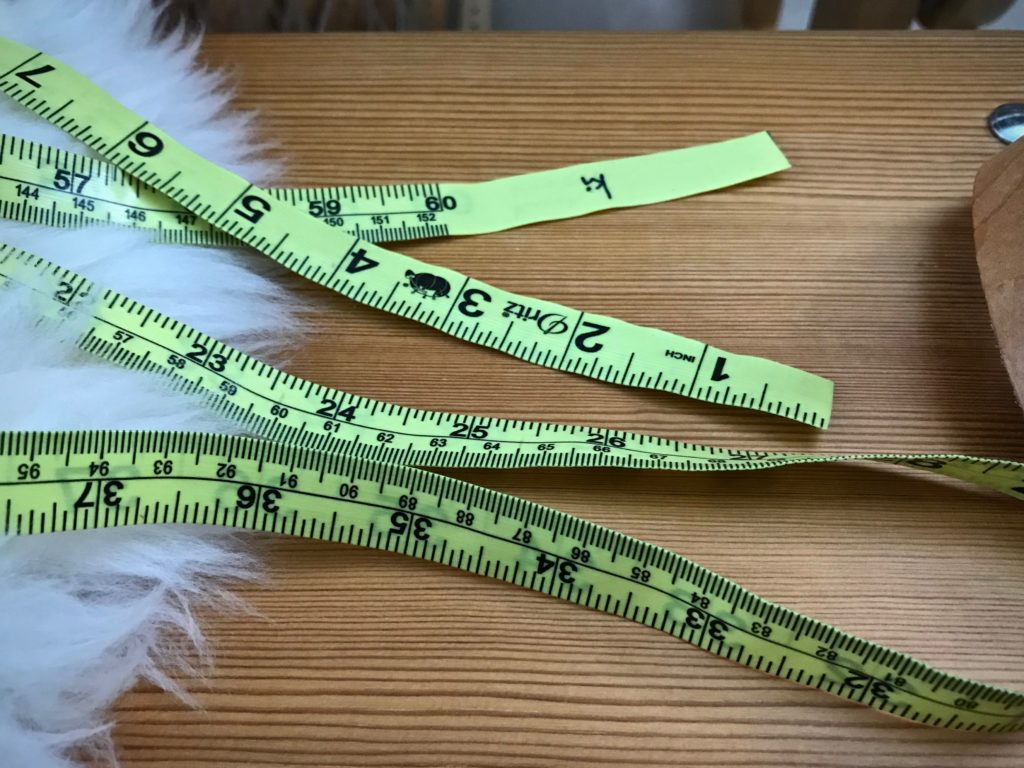

A tape measure is a weaver’s best friend. Think about how many ways the tape measure serves you. I have one at each loom. Always. And I have a few others scattered around, hanging up, and in bags. Because you never know when you might need to measure something.

Tape Measure Uses

- Take measurements to determine the desired size of the finished cloth, such as window measurements for curtains, floor space for area rugs, or length of skirt tiers for skirt fabric.

- Measure the length of a guide string for winding the warp.

- Find the starting point for the warp width in the pre-sley reed.

- Double check the width of the warp after it is pre-sleyed.

- Check the width of the warp on the back tie-on bar.

- Center the reed in the beater for beaming the warp by measuring the distance from the warp in the reed to the outside edge of the beater on both sides.

- Find the starting point to sley the reed by measuring half of the warp width outwards from the center of the reed.

- Double check the width of the warp in the reed after it is sleyed.

- Center the reed in the beater for weaving.

- Adjust to the correct width of the warp on the front tie-on bar after the warp is tied on.

- Mark the measured weaving length on twill tape or ribbon to use as a weaving length guide.

- Measure how far one quill weaves.

- Measure the distance between pieces that require unwoven warp, such as for fringe, or for tying knots between rag rugs.

- Measure the distance from the first shaft (nearest the back of the loom) to the back tie-on bar (especially when you are hoping there is enough warp left to finish a symmetrical pattern).

- Measure the width and length of fabric that is cut from the loom.

- Measure the width and length of fabric that has been wet finished, dried, and pressed.

- Measure your pleasure at the loom. Immeasurable!

What have I missed? Can you think of other ways your tape measure comes in handy?

May you be blessed in full measure.

All the best,

Karen