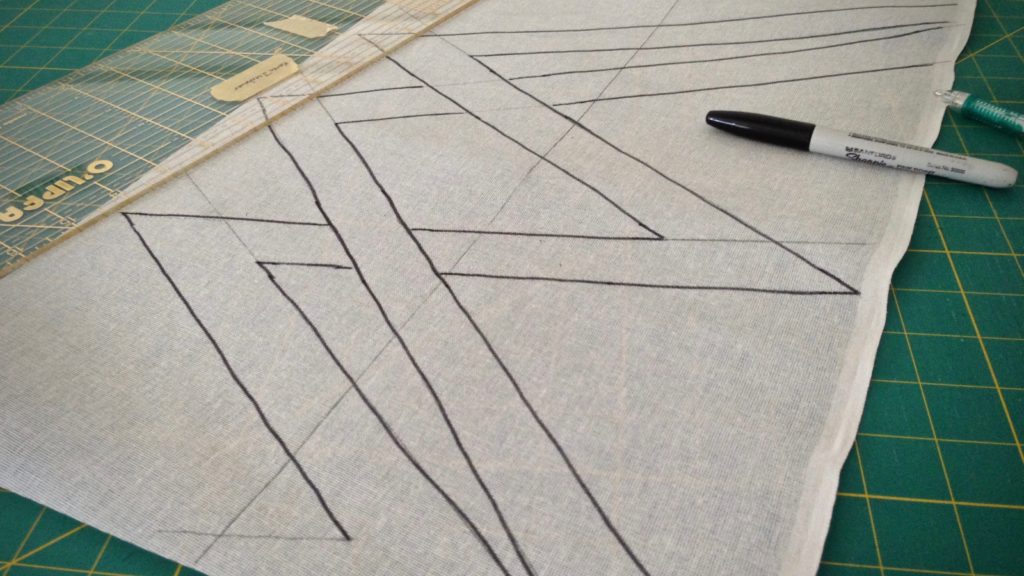

Weaving a transparency could become one of my favorite things to do. I had no idea that drawing a cartoon for this project would make such a difference. Now, I can see vast possibilities with this weaving technique.

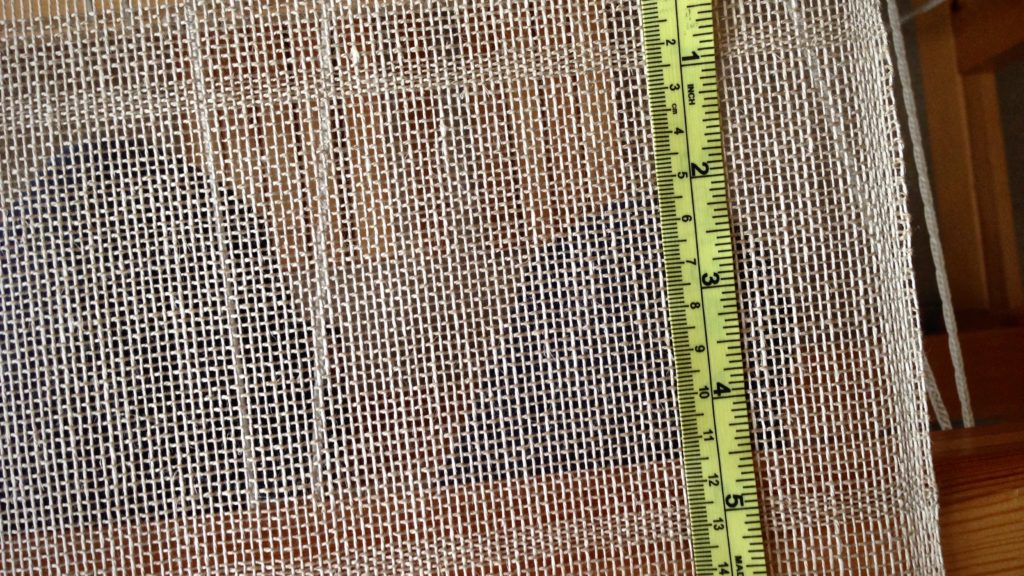

I started the transparency without a cartoon. I wanted to weave a few zigzags back and forth. How hard could that be? I counted warp ends, “under 12 to the right, and then, under 13 to the left.” When I tried to change the angle of the slant, though, it was confusing. I started getting jagged zigs and zags. This cartoon has made a world of difference.

How often do we think it will be easier to go our own way? We want to make it up as we go. Wait. There’s a better way. The head designer has drawn out a path. It makes sense to follow those lines. It’s a picture that’s bigger than we are. God created. He did it in such a way that shows his loving attention to those he created. And we get to follow his design. No more striving. No more trying to find our way. His way makes perfect sense. It’s satisfying to place the weft in a thought-out design.

May you see the possibilities.

Happy Weaving,

Karen