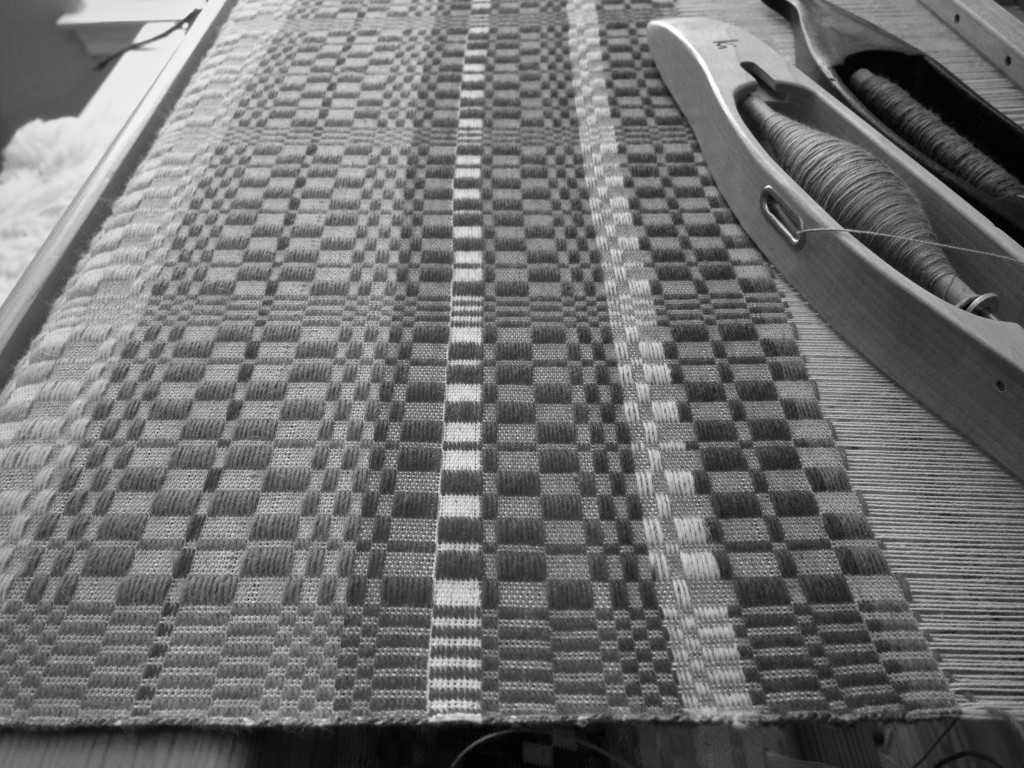

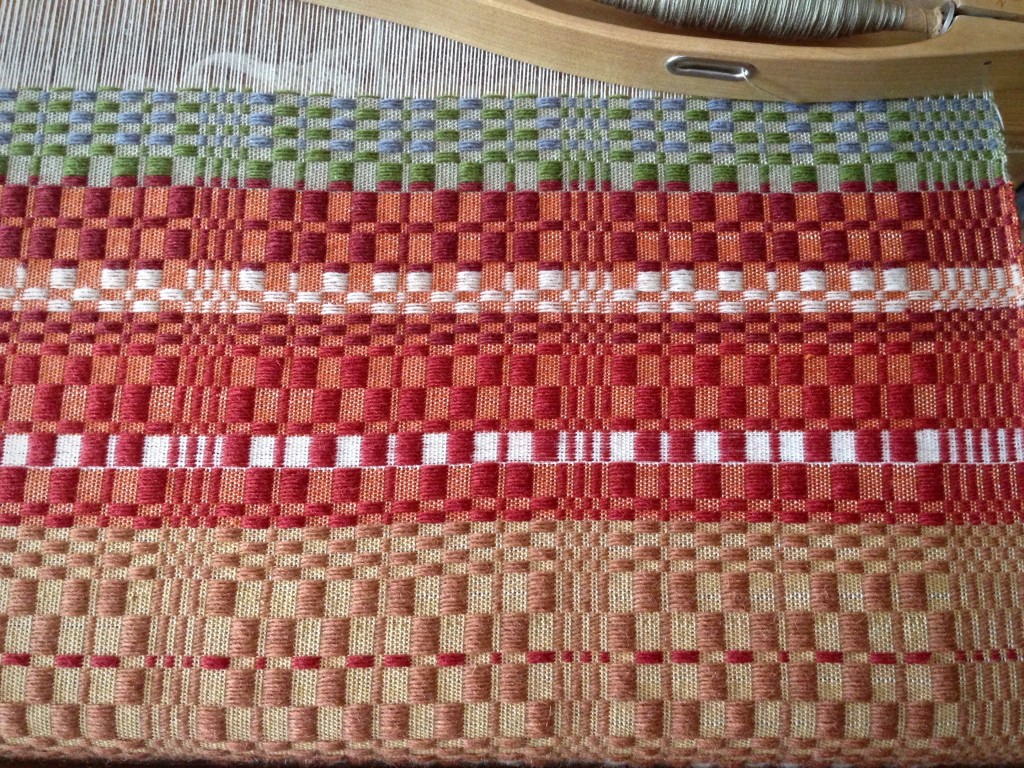

I almost kept going. But something was off. Maybe the tabby hadn’t been beaten in as tight between the lavender pattern picks. In that case, a few more rows would obscure the slight difference. I did not want to undo; and wishful thinking tempted me to avoid taking a closer look. Sensibility won, though. I did stop to examine the cloth.

Even under close inspection, my eyes could not identify the error. I struggled to see the fine details. Magnifying glass to the rescue! Magnification revealed two extra tabby picks. Aha! Two fine threads out of place are enough to throw off the pattern. If not corrected, this errant line across the finished cloth would draw the attention of every eye. Knowing precisely where the error is gives me courage to face the necessary operation. Snip, snip, snip. Undo. Fresh start.

An honest report tells it like it is. When we are trusting the Lord, we have courage to stop and examine errors, bypassing wishful thinking. Faith is like a magnifying glass that enables us to see clearly. Courage comes alive through the eyes of faith. The difficult and painful process of undoing errors and making corrections is worth it when you consider the high value of the finished fabric.

May you catch your errors while they can be undone.

Honestly,

Karen