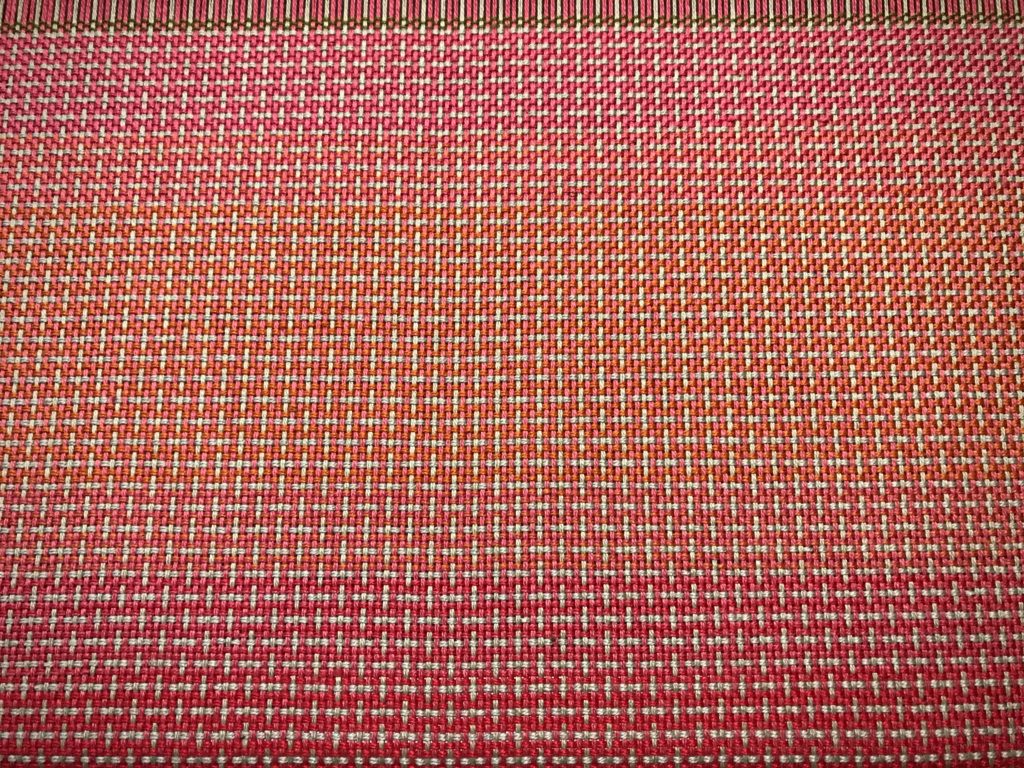

When I decided to use up some of the quills that have collected, I stumbled on one of my favorite techniques—color gradation. The weft colors change gradually instead of making distinct weft stripes. Remember the placemats on the little countermarch loom? I am weaving the last few.

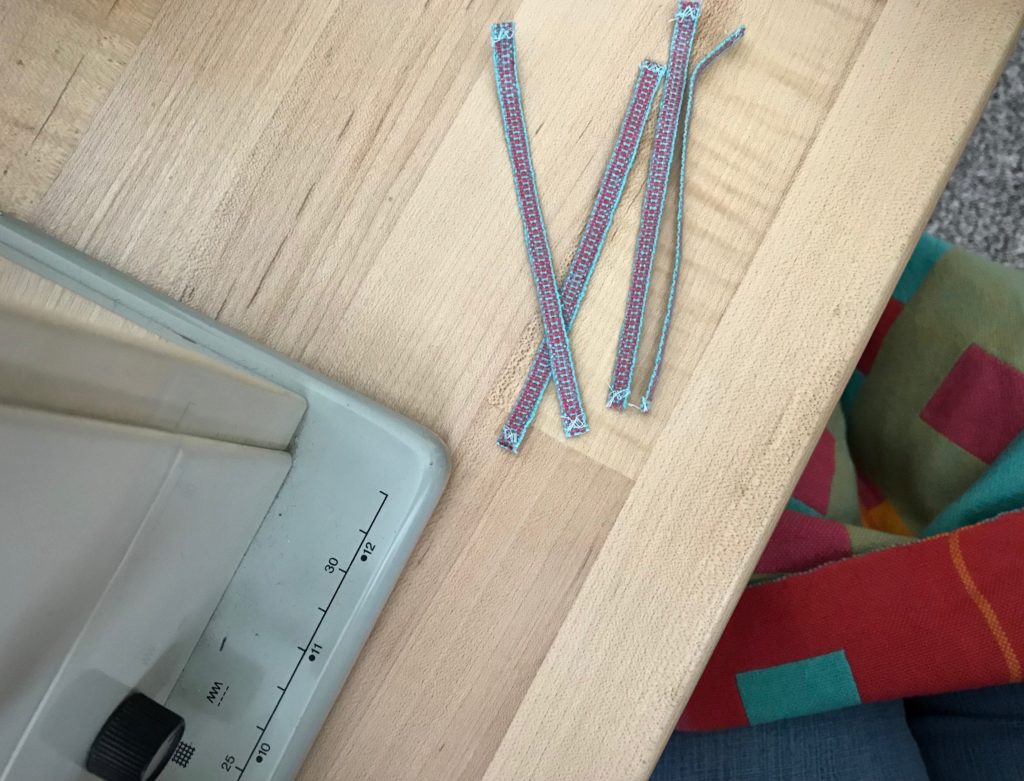

The quills on a double-bobbin shuttle don’t always empty at exactly the same time. The quill that has thread remaining on it goes in a box for later use. Those quills in the box are what I’m using here. For this placemat I’m letting gradient color changes happen in varying increments, according to the amount of thread left on the quill. I have five shades of 8/2 cotton, ranging from coral pink to pumpkin.

This is the perfect setup for some subtle color gradation: Five closely-related hues, a double-bobbin shuttle, and a supply of leftover quills. For best effect, I arrange the colors in order, from light to dark, or dark to light.

Color Gradation

- Weave a section with two quills of color A (the lightest color)

- Weave the next section with one quill of color A and one quill of color B (one shade darker than color A)

- Weave the next section with two quills of color B

- Weave the next section with one quill of color B and one quill of color C (one shade darker than color B)

And so on…

What could be simpler?

May you make something beautiful with the little bits that you have.

Happy weaving,

Karen