I warped the drawloom with gray 6/2 Tuna wool several months ago with the goal to make fabric for a reversible vest. The beautiful drawloom fabric turned into dreamy garment-worthy fabric after washing! (See Process Review: Drawloom Jewels)

And then I hit two huge hurdles.

Hurdle 1. Fit.

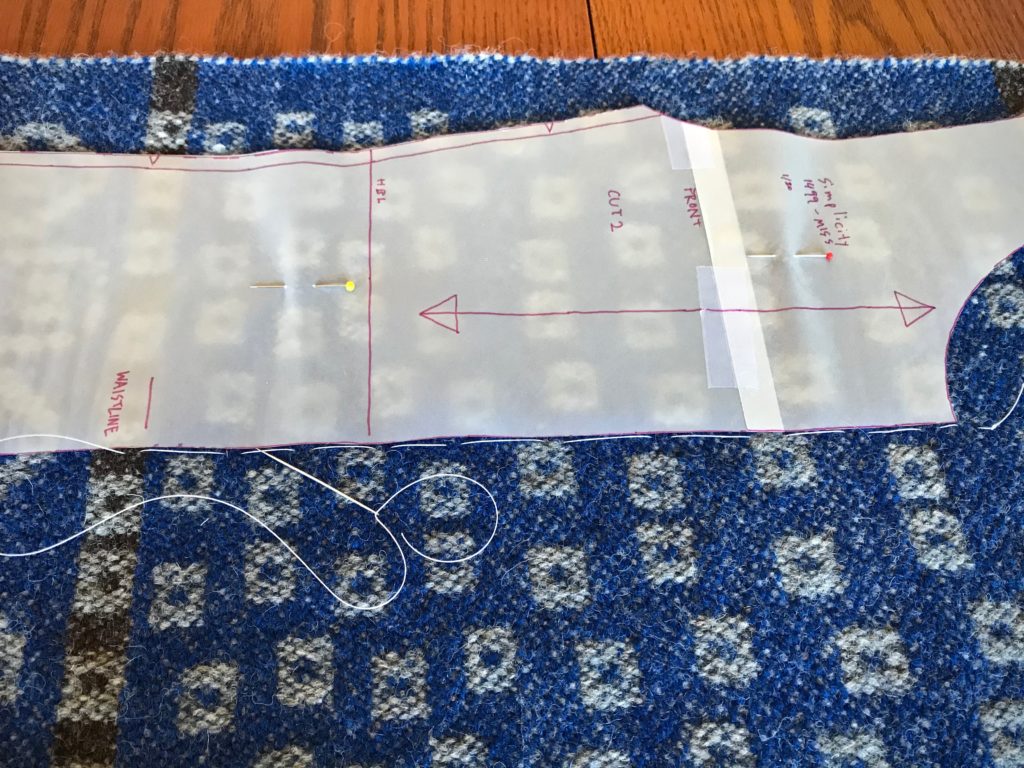

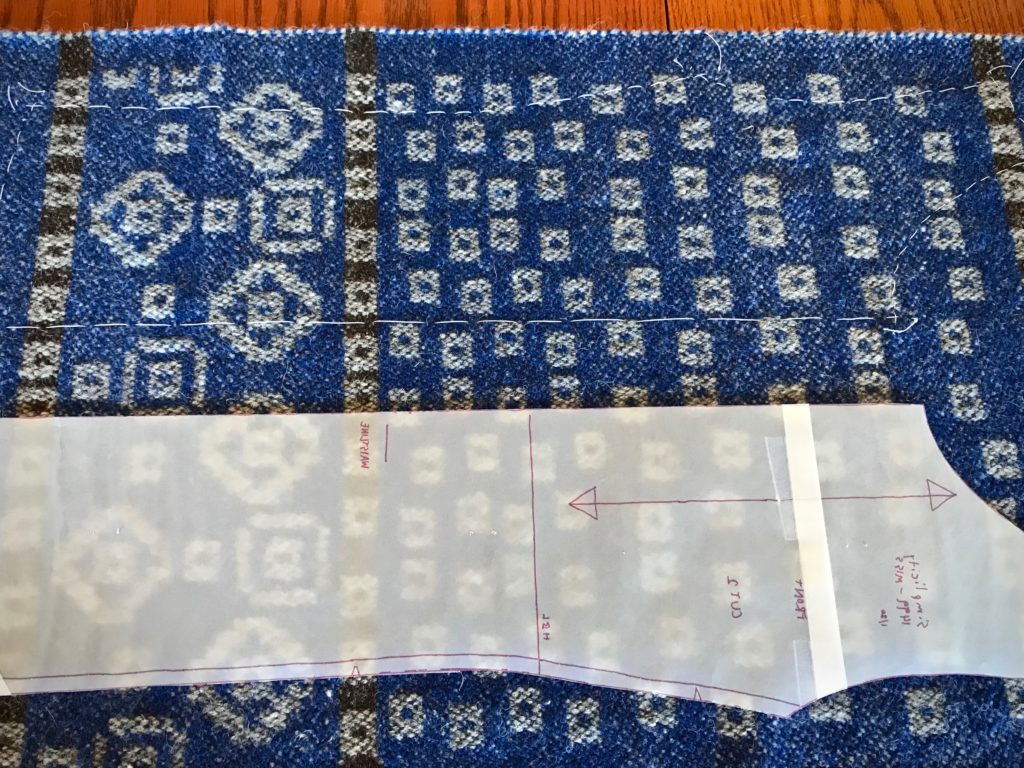

In order to cut into handwoven drawloom fabric, I need assurance that the end result will fit me. My sewing assistant helped me refine a commercial pattern.

After umpteen muslins and two or three mock-ups, I finally got the fit I was after. Confidence to cut!

Hurdle 2. Garment Construction Uncertainties.

Do some detail studies, my dear friend Elisabeth said to me. Her advice got me over the insecurity hurdle. A detail study is making a small sample to test a hypothesis or answer a question. I made a list of everything I wanted to know about constructing a vest from this type of handwoven wool fabric. And then, using some of the extra fabric from the sampling at the beginning of the warp, I did a detail study for each point on the list. Twelve detail studies in all.

(If you are interested in seeing my complete list of 12 detail studies for this project, click HERE to send me an email and ask for my “Detail studies”.)

Here are a few examples of my findings:

- Zigzag before or after cutting? // Zigzag before cutting, stitch width 3, stitch length 2 1/2

- Lapped seams? 3/8”, 1/2”, 5/8”? // Yes, lapped seams, overlap 1/2”, stitch basted line to guide placement

- Neck and armhole curves – staystitch with hand running stitches or machine stitching? 1 row or 2? // Hand running stitches, 2 rows

From the results of the detail studies I was able to compile a step-by-step garment construction plan. Confidence to sew!

Follow my process pictures of the garment construction to see the results:

May you find ways to leap over your hurdles.

Love,

Karen