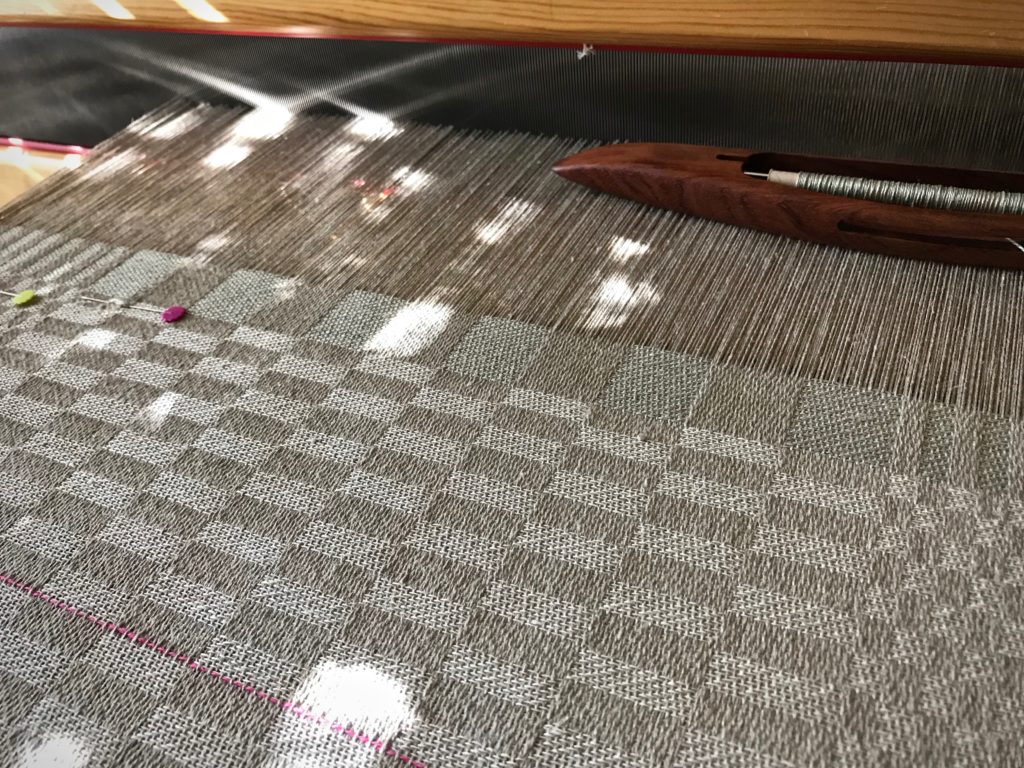

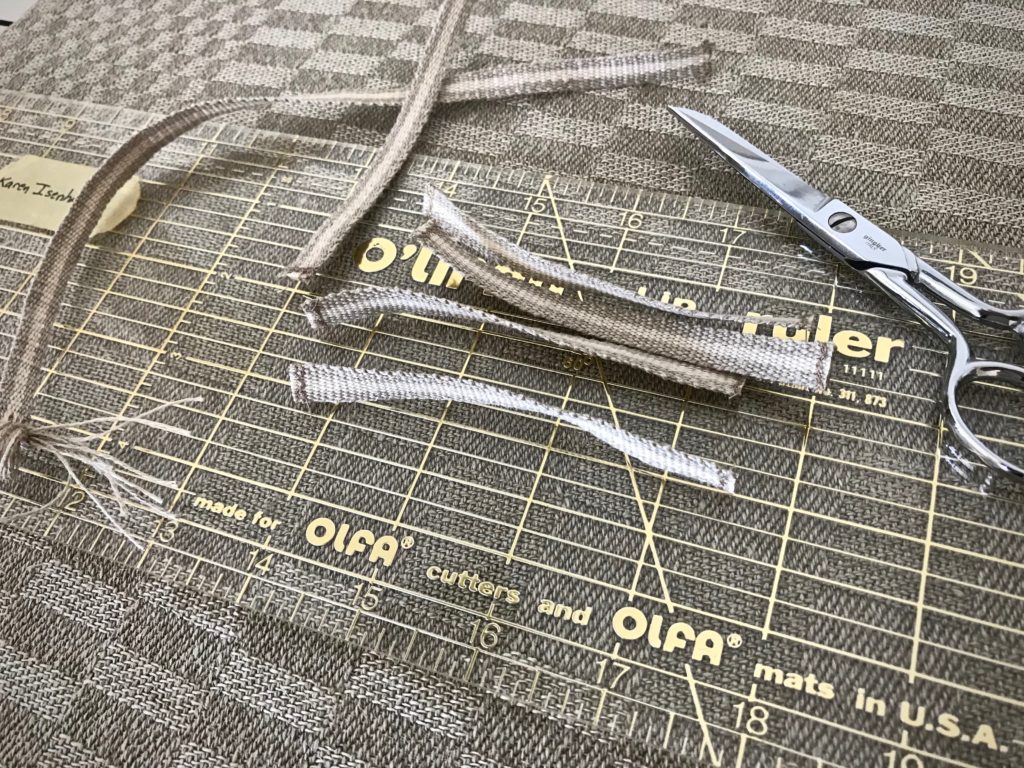

There are four pairs of overlapping warp chains, with stripes to line up. I created a mess. A few options to consider: 1. Give up. 2. Weave it as is, destroying the design. 3. Use two sets of lease sticks, and expect problems with threading (2,064 ends). 4. Transfer all ends to a single set of lease sticks, arranging threads in order for each stripe.

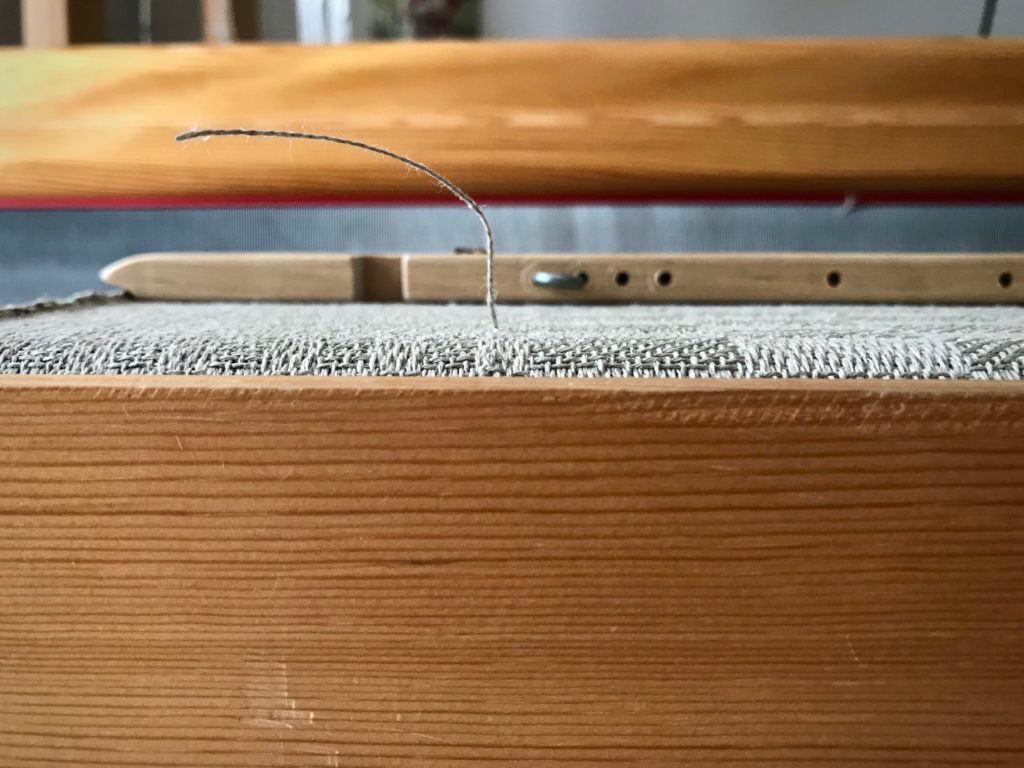

Option 4 seems the riskiest. If I lose the cross while transferring threads, I have an even bigger mess. It’s all or nothing. Go for it! Fortunately, my apprentice, Juliana, arrives in the nick of time to give me a hand.

It worked! All the threads are successfully transferred to one pair of lease sticks. What a relief! I can beam the warp knowing that all is well. A beautiful double weave throw is imminent.

We all have made a mess of our lives, and we know it. We hear of options to fix things, but one seems the riskiest: Transfer everything to God. But what if I mess that up, too? There’s good news. God transfers us. When we place our trust in Jesus Christ, God transfers us from our messy state to his good order. And the result is a weaving that showcases his workmanship—a beautiful you.

May you take a worthy risk.

With you,

Karen