When I pick up a color of thread I don’t want to have to guess if it’s the right color. Four of the five blues in the weft sequence are close neighbors in value. The one color that is easy to identify is the navy blue, which provides a good contrast among the blues.

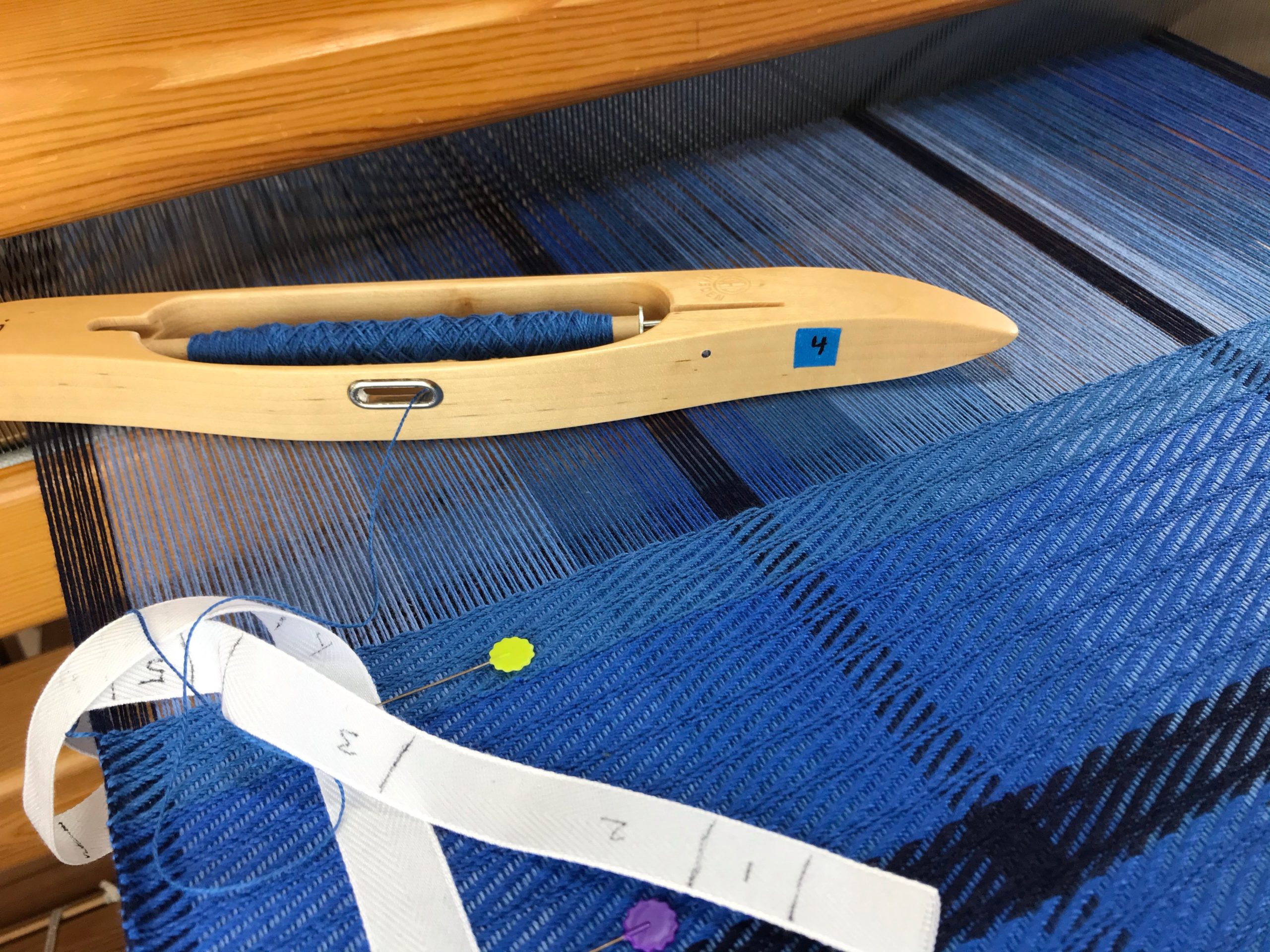

The weft order matches the warp order, and is marked out on a ribbon. I am using a separate boat shuttle for each shade of blue. But how do I know which color is which, when the difference is subtle from one color to the next?

Simplify Subtle Color Changes

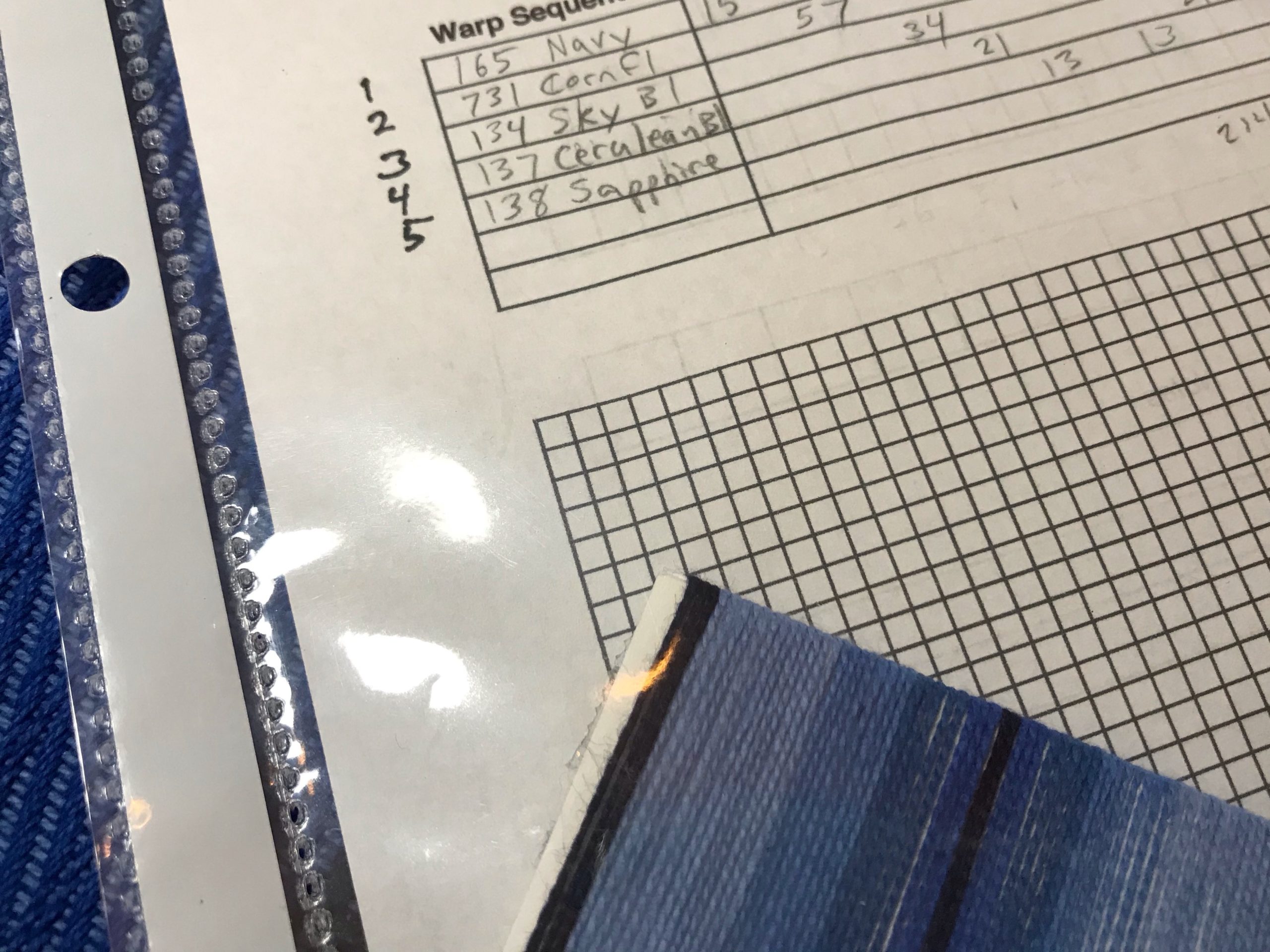

- Give each color a number. Write the numbers next to the colors of the warp order on the Project Notes.

- Label the thread tubes with a small piece of blue painter’s tape. Each tube of thread is numbered to correspond with the numbers on the Project Notes.

- Label each boat shuttle with its assigned color number, using a small piece of blue painter’s tape.

- Place wound quills under the rubber band of their respective thread tubes.

It is easy to keep track of these five numbers as I follow the weft sequence that is marked on my reference ribbon. Now, it’s shuttle #4’s turn…

May you find a way to simplify.

Happy Weaving,

Karen