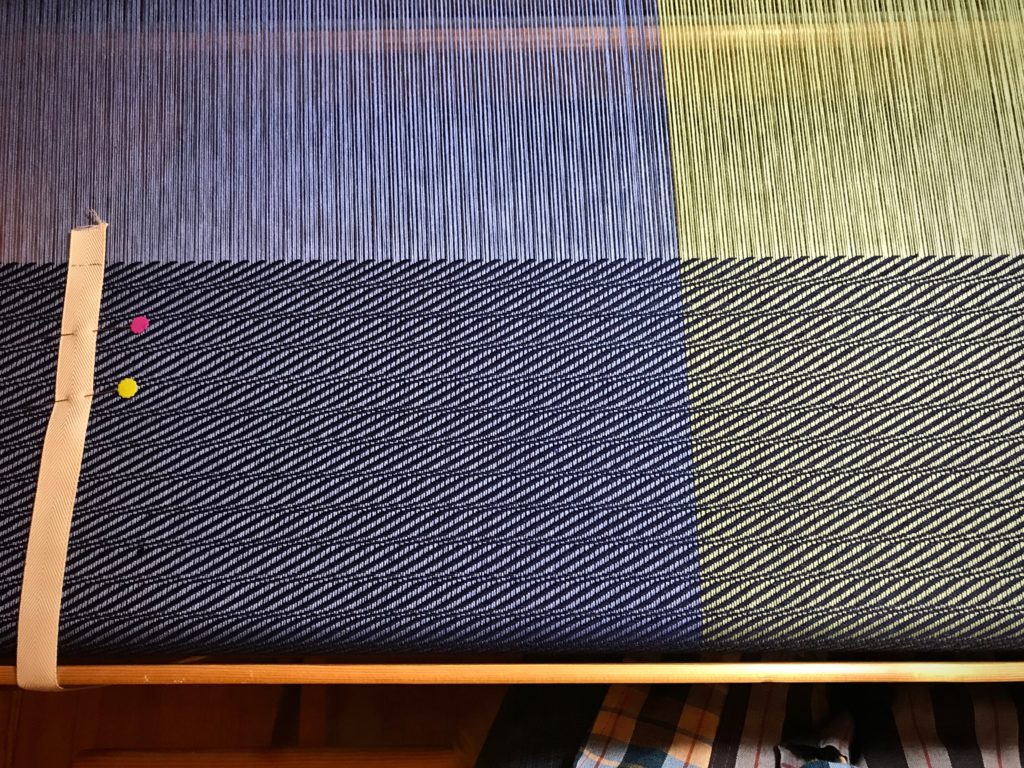

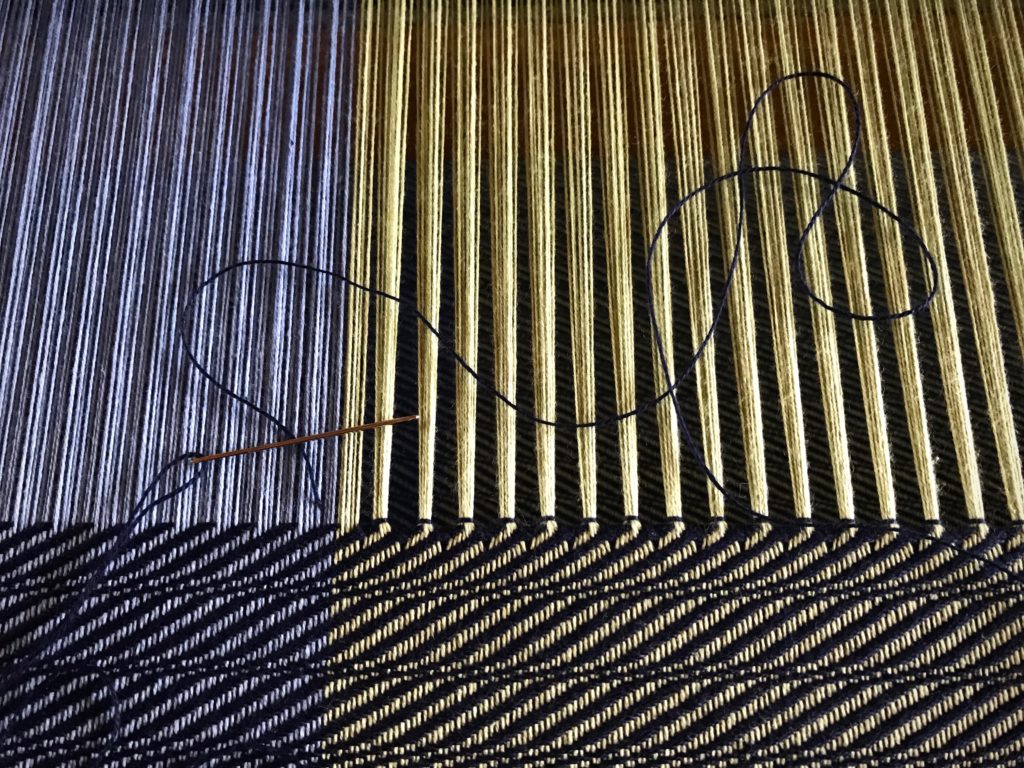

Hemstitching gives a secure and pretty edge for the fringe on this cotton throw. At the beginning of the throw, I measure out a length of the weft thread for the stitching. And now, at the end, I roll off enough thread from the shuttle’s quill to use for the final hemstitching.

I’m always afraid of cutting the length of thread too short. So, I measure off four times the width of the warp, with a pinch extra just in case. That’s too long, and I know it. But I do it anyway. And then, I have a very long thread to pull through every stitch, with the tangles and knots that go with it.

In trying to be perfect, I miss perfection by a long shot. If I measure out more than enough of my own goodness, surely I’ll have plenty to enter heaven, right? But the perfection of heaven requires perfection. It’s impossible for me to be good enough, smart enough, or successful enough to reach perfection. Heaven is for the imperfect. We, the imperfect, enter heaven’s perfection by trusting in the only perfect one, Jesus Christ. His goodness, measured out for us, is precisely enough.

May you know when enough is enough.

Happy weaving,

Karen