How much more thread will a 13cm quill hold than an 11cm quill? In other words, how much further can I weave with the longer quill? I decided to do a simple test to find out. Which size quill should I use for the rest of this project?

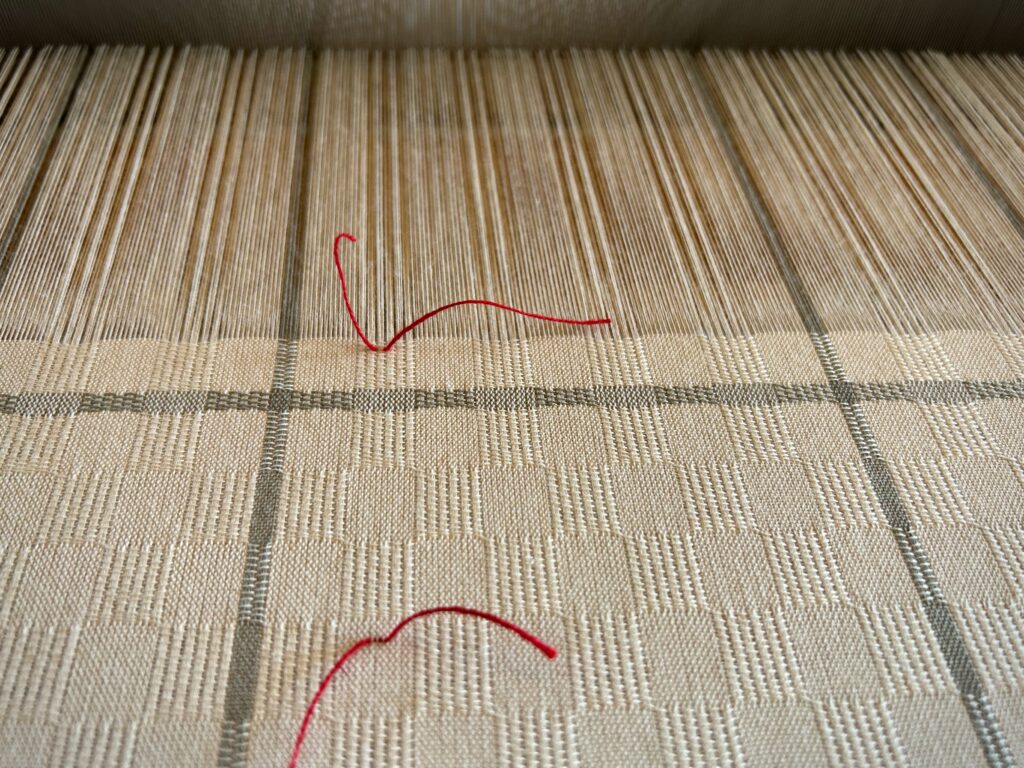

First, I mark the beginning of the 11cm quill with a short red thread woven through a few ends on the same row as the first row of weft from that quill. I weave off the thread from that quill and weave in another short red thread on the final row of the quill, putting the second red thread directly above the first red thread. Now, I can measure the distance that the quill’s weft covered the warp, minus the gray weft stripe. I repeat the test with another quill so I can average the difference, if any. I find that both quills cover exactly 6 cm of warp. How’s that for consistency in winding my quills?

Time to test the 13cm quill. I do this exactly the same way, including the repeat test. The result? The 13cm quill covers 7.2 cm of warp. So there is 1.2 cm difference between the shorter quill and the longer quill.

I have a total of 8.6 meters to weave on this curtain fabric (about 1.5 meters already woven). That means winding about 143 quills (11cm), or 119 quills (13cm). Not much difference, really. Still, I’m in favor of winding 24 fewer quills of 24/2 cotton. Aren’t you?

May the math work in your favor.

Happy Weaving, Karen