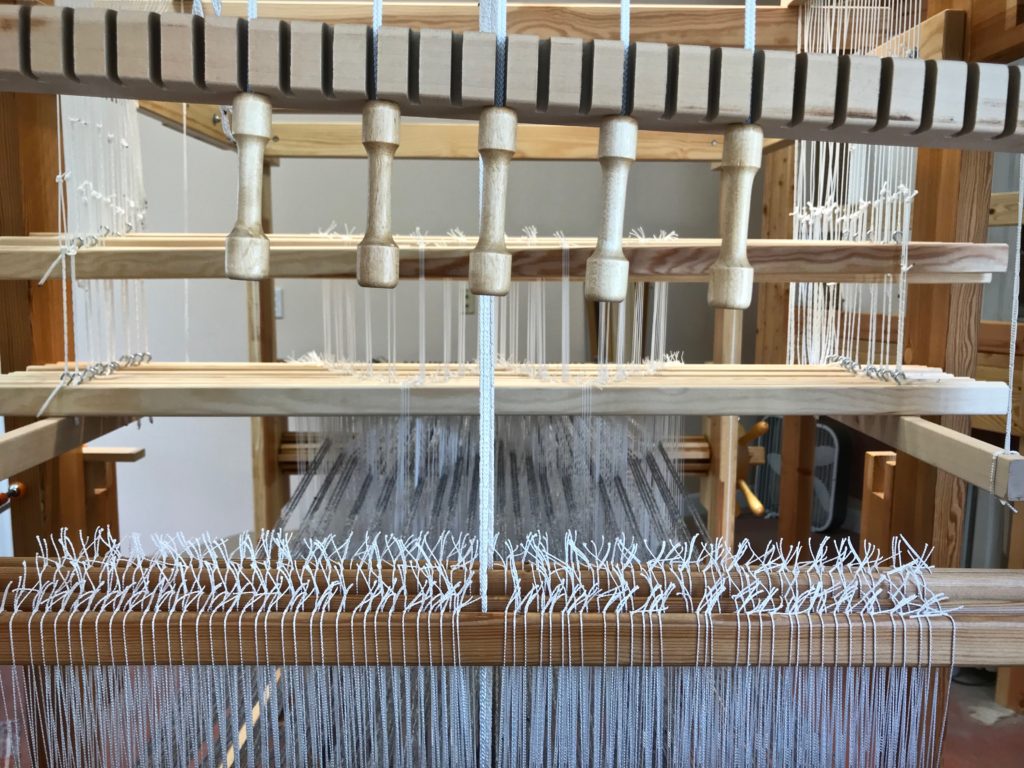

“With so many looms, how do you decide what to weave every day?,” I was asked. The answer lies in my Weaving Rhythm. I have five floor looms. I happily aspire to meet the challenge of keeping all of them active.

Glossary

Weaving Rhythm ~ A pattern created across time, through a regular succession of weaving-related tasks.

Arrange individual tasks to keep each loom consistently moving forward in the weaving continuum.

Weaving Continuum ~ The cycle for each loom that is continually repeated.

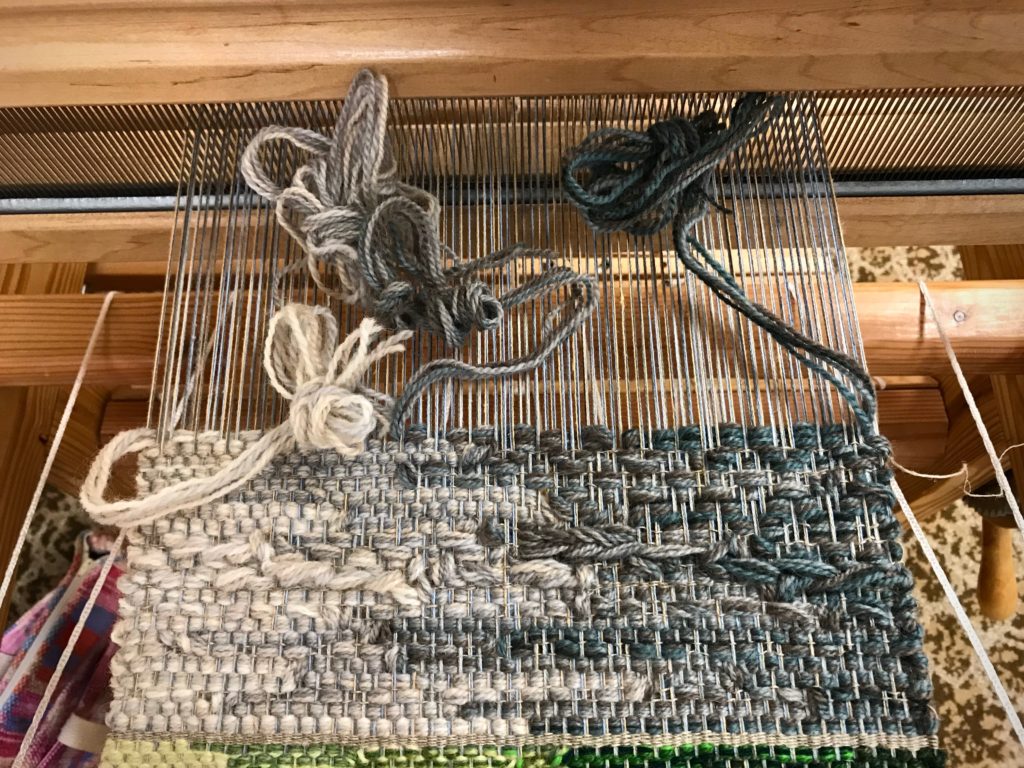

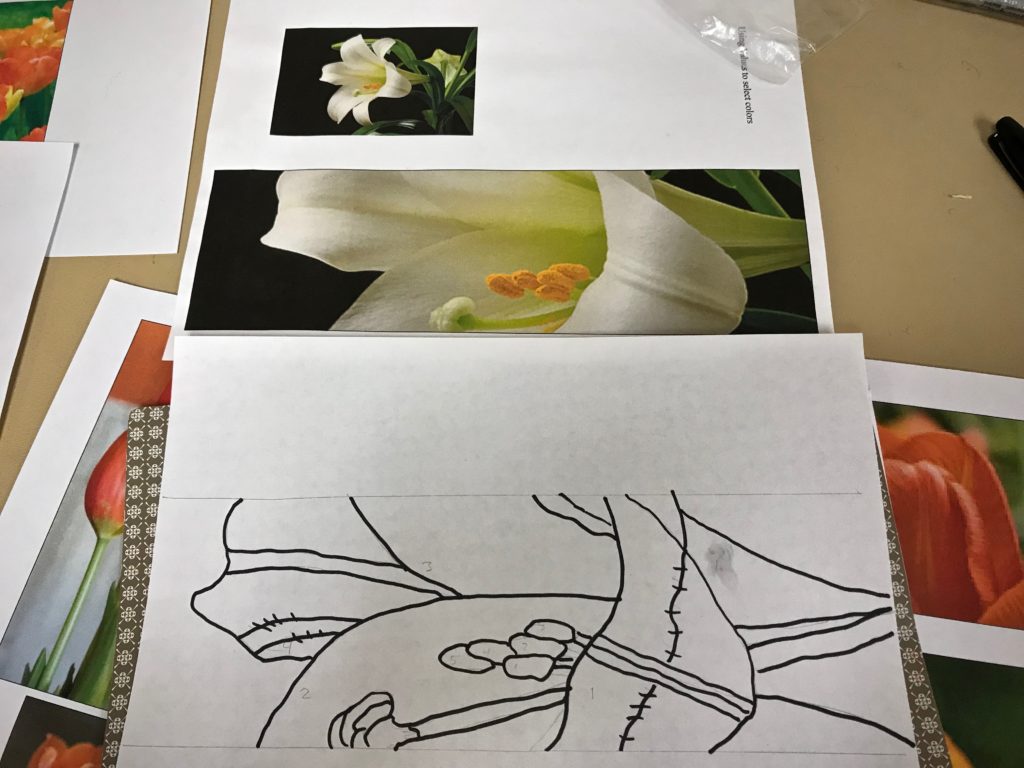

When the first few centimeters are woven on a new project, begin planning the next project. When finishing is completed for the current project, wind a new warp and dress the loom for the next project.

First Things First ~ Prioritize daily tasks to maintain the Weaving Rhythm.

- Finishing

- Dressing

- Weaving

Do some finishing work first. Do some loom-dressing tasks next. The reward, then, is sitting at one of the dressed looms and freely weaving for the pleasure of it.

Give Thanks ~ Live with a thankful heart.

Every day I thank the Lord for granting me the joy of being in this handweaving journey. And I thank him for bringing friends like you along with me.

May you always give thanks.

With a grateful heart,

Karen